“Turn the faucet off while you’re brushing your teeth! You’re wasting water.”

Growing up, I heard these words often.

“Turn the faucet off while you’re brushing your teeth! You’re wasting water.”

Growing up, I heard these words often.

In the October 2020 issue of Compact Equipment, Navendu (Nav) Sharma, Senior Product Manager at Sullair, discusses winterizing tips for portable diesel air compressors.

Have you ever considered climbing Mount Everest or Mount Kilimanjaro and thought there is no way you would be able to survive the harsh conditions?

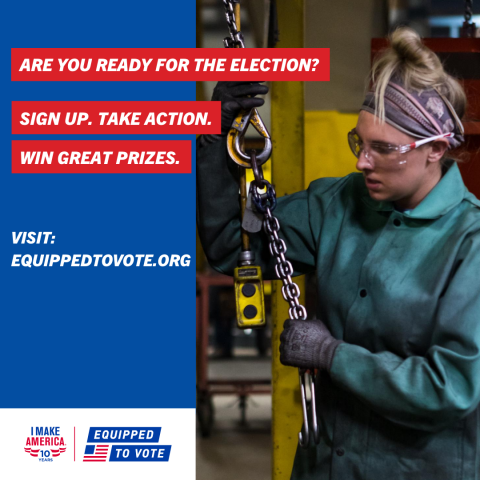

Last month, Association of Equipment Manufacturers (AEM) launched Equipped to Vote, a digital campaign designed to engage, educate, and mobilize the 2.8 million men and women of the equipment manufacturing industry leading up to the gener

The Food & Beverage industry was shaken up in 1997 when a consumer packaging expert found mineral oil in a vacuum-sealed sausage package.

It's something no food or beverage manufacturer can operate without.

Navendu Sharma, Senior Product Manager with Sullair, provided commentary in the September 2020 issue of Compact Equipment.

As a facilities manager or business owner, you know how important it is to maximize the efficiency of your compressed air system. Especially now, more than ever, when money may be tight and savings need to be realized.

For an industrial compressed air system, removal of moisture from the compressed air stream is a vital task. Dry compressed air helps keep air-powered tools, equipment, and instruments running well.

It’s almost that time of year again. Time to ensure your irrigation (lawn sprinkler) system is blown out.

Manhar Grewal, R&D Product Manager at Sullair, recently had an article published in Compressed Air Best Practices titled "Calculating the Water Costs of Water-Cooled Air Compressors."

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.