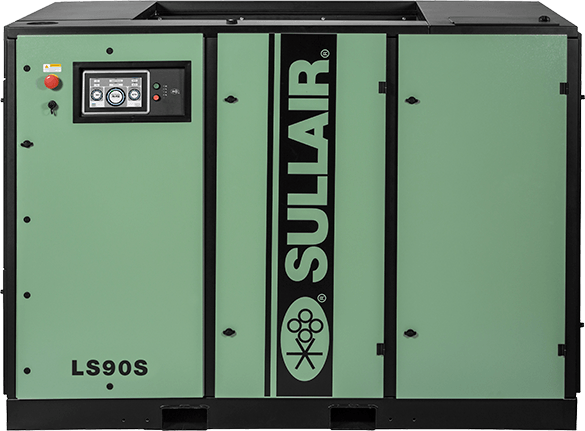

When your operation depends on compressed air, reliability, durability, and performance matter. The dynamic range of Sullair oil flooded industrial air compressors helps provide peace of mind at any step of your operation.

These key pillars consistently drive the quality of Sullair compressed air solutions. It’s a promise we keep with every machine we make.

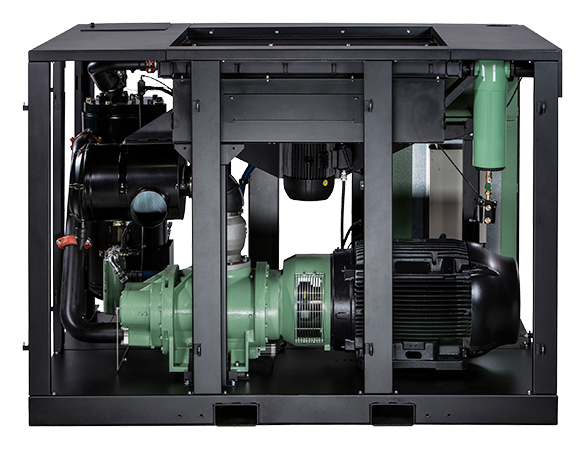

The heart of a Sullair industrial air compressor is the Sullair Air End.

The heart of a Sullair industrial air compressor is the Sullair Air End.

We have more than five decades of experience with rotary screw technology, and we keep finding ways to improve it.

These decades of proven reliability are a testament to the quality of the Sullair Air End.

Benefits of the Sullair Air End include:

Accessible Components

Accessible ComponentsSullair compressors are designed with accessible components for maintenance and servicing. Many models feature removable hinged door panels that are simple to remove, making service and maintenance quick and easy.

When you invest in a Sullair compressor, you get more than just an asset in your facility — you also get local service and support. Experienced service technicians, backed by our global distribution network, are ready to provide quick and easy service and maintenance.

Contact your Authorized Sullair Distributor to schedule:

10-Year Diamond Warranty

10-Year Diamond WarrantyReinforcing rugged durability and commitment to customer satisfaction, all new Sullair lubricated stationary compressors up to 150 psi / 10 bar come with the exclusive 10-Year Diamond Warranty. The comprehensive warranty covers:

Maintaining the Sullair 10-Year Diamond Warranty requires using Genuine Sullair parts and Sullube, as well as the oil sampling program.

ShopTek compressors and all new Sullair lubricated stationary air compressors with discharge pressures over 150 psi / 10 bar are covered by the 5-Year Emerald Warranty, which provides coverage on major components including:

Customers share their stories of how Sullair Industrial air compressor solutions contribute to their success.

Compressed Air – the Fourth Utility

Compressed Air – the Fourth UtilityWith compressed air being used in more than 70% of manufacturing processes, your compressed air system can be a huge opportunity for energy savings¹.

Increasing compressed air system efficiency can help lower your operating costs.

Authorized Sullair Distributors are true air compressor experts and can perform full system air audits to identify inefficiencies within your existing system and provide you with the best solution to save money.

A full system air audit can help identify:

Contact your Authorized Sullair Distributor to schedule a full system air audit. Distributors can provide options and a customized plan to help maximize efficiency and reduce energy, maintenance and equipment costs.

¹ U.S. Department of Energy, Assessment of the Market for Compressed Air Efficiency Services.

Don’t risk your compressor’s performance — or your warranty — by using imitation parts. Count on Sullair Genuine Parts and Fluids to maintain the health of your air compressor.

Sullair Genuine Parts and Fluids:

Increasing compressed air system efficiency can help lower your operating costs.

When you choose Sullair Genuine Parts, you are using components engineered for the optimal performance of your Sullair compressor.

Industrial Air Compressor Parts from Sullair:

It’s vital to trust what goes into your air compressor as much as the machine itself. Sullair Genuine Lubricants are specifically formulated to optimize compressor performance and help extend compressor life.

Industrial Air Compressor Fluids from Sullair:

Contact your Authorized Sullair Distributor for Sullair Genuine Parts and Genuine Sullair Fluids.

Sullair is prominently featured in the May 2020 issue of Compressed Air Best Practices magazine.

With summer here, most of us only want to think about sunny days, beaches, barbecues, and baseball games. One thing to avoid ‘playing games’ with is your industrial air compressor maintenance.

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.