Water jeopardizes everything you want your compressed air system to do. Failure to remove this water ruins product and fouls process. A reliable air treatment system is vital to help protect your equipment and your operations.

Also, a complete air treatment system can help optimize air flow thus helping lower your operating costs.

Clean, Dry Compressed Air Is Critical For All Operations

Moisture and contaminants can pose a huge risk to your operation. That’s why an efficient air treatment system is vital to help keep your air stream clean and dry.

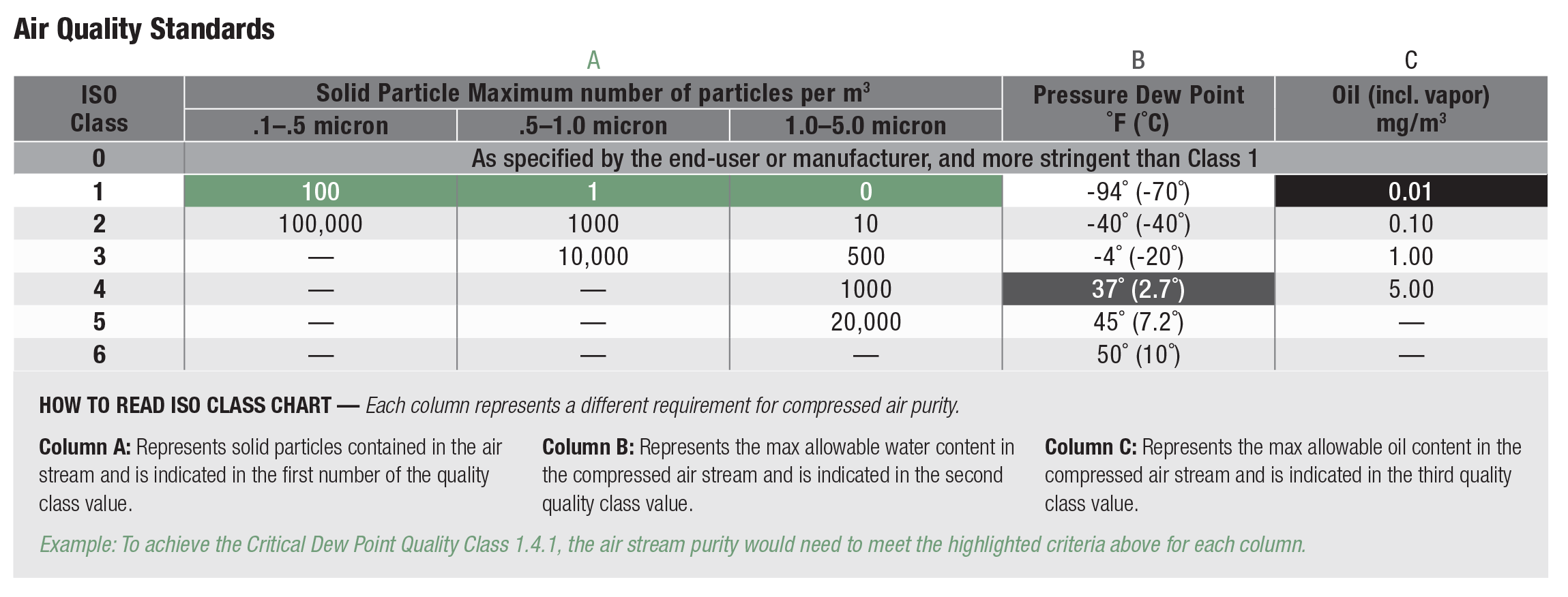

ISO standards are globally recognized and used for quality assurance in most industries. For compressed air, ISO 8573-1 classes determine air quality standards. To determine air quality standard for operations, three parameters are used.

The diagram on the right and chart below can help determine air quality standards and how to achieve the correct air purity level.

Ideal for Applications Requiring Extremely Low Dewpoint

Sullair Desiccant Compressed Air Dryers are engineered for the most critical applications — providing dry compressed air where you need it most.

Sullair Desiccant Dryers have a dual tower design in which both vessels are filled with desiccant material. Moisture migrates to the driest material available. Desiccant material adsorbs moisture—separating it from saturated compressed air. (As long as the desiccant material is drier than the air entering the dryer.)

Desiccant dryers are classified by regeneration methods.

Uses an average of 15% of process air during the regeneration process

Uses an average of 8% of process air during the regeneration process

Uses an average of 2% of process air during the regeneration process

Sullair Refrigerated Air Dryers reliably remove harmful moisture and contaminants from compressed air, helping protect your compressed air system, machinery and downstream tools.

The dried, cool process air passes back through the heat exchanger to be reheated and help prevent condensation outside of the downstream distribution piping.

For an industrial compressed air system, removal of moisture from the compressed air stream is a vital task. Dry compressed air helps keep air-powered tools, equipment, and instruments running well.

With the growing presence and demand for compressors producing Class 0 oil free air, it is easy to get confused regarding how to read, and understand, the ISO 8573-1:2010 Air Quality Classes chart. To truly understand the chart just like the alphabet we begin with our ABC’s:

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.