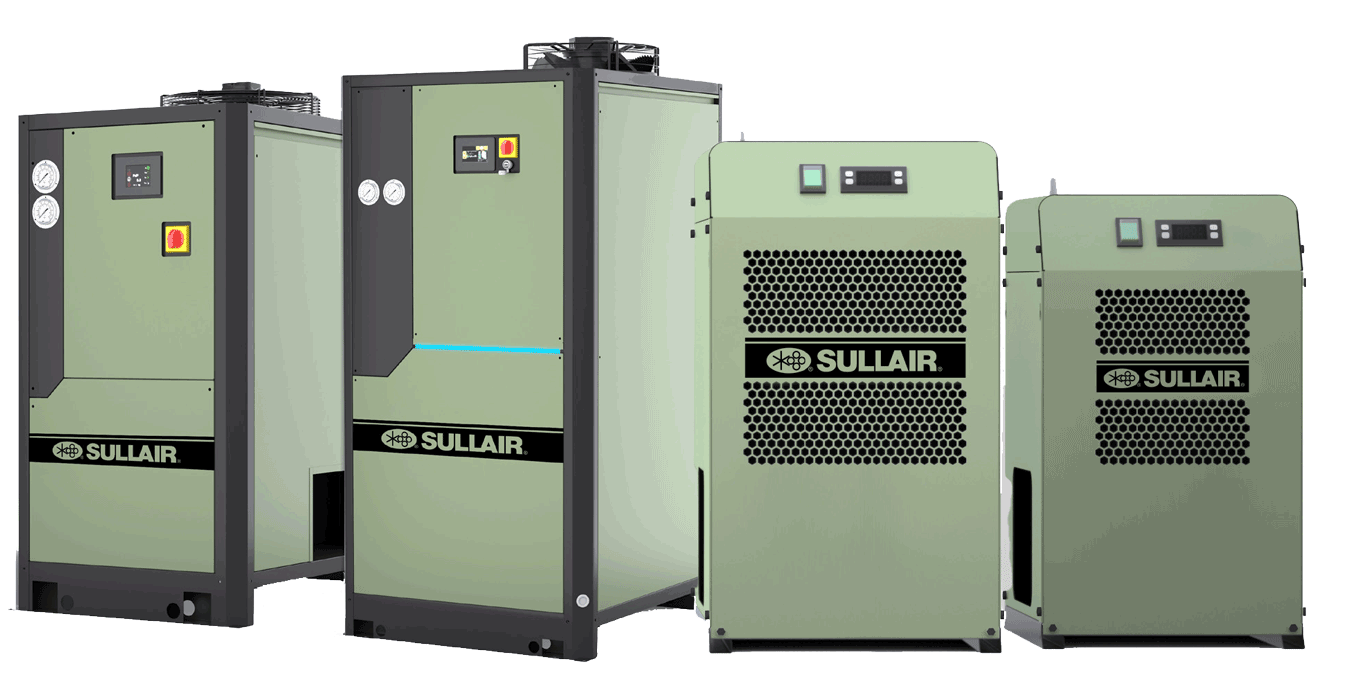

ENERGY EFFIECIENCY. LOW PRESSURE DROP. SUSTAINABILITY.

Sullair Refrigerated Compressed Air Dryers focus on energy-efficiency, sustainability and maintaining a stable dewpoint in all operating conditions.

- All-In-One Heat Exchanger for optimized efficiency and low pressure drop

- Low Global Warming Potential (GWP) R-513A refrigerant

- Easy-service design with a compact footprint

Models vary by region. Please contact your Sullair sales representative for more details.