CLEAN, DRY COMPRESSED AIR IS ESSENTIAL

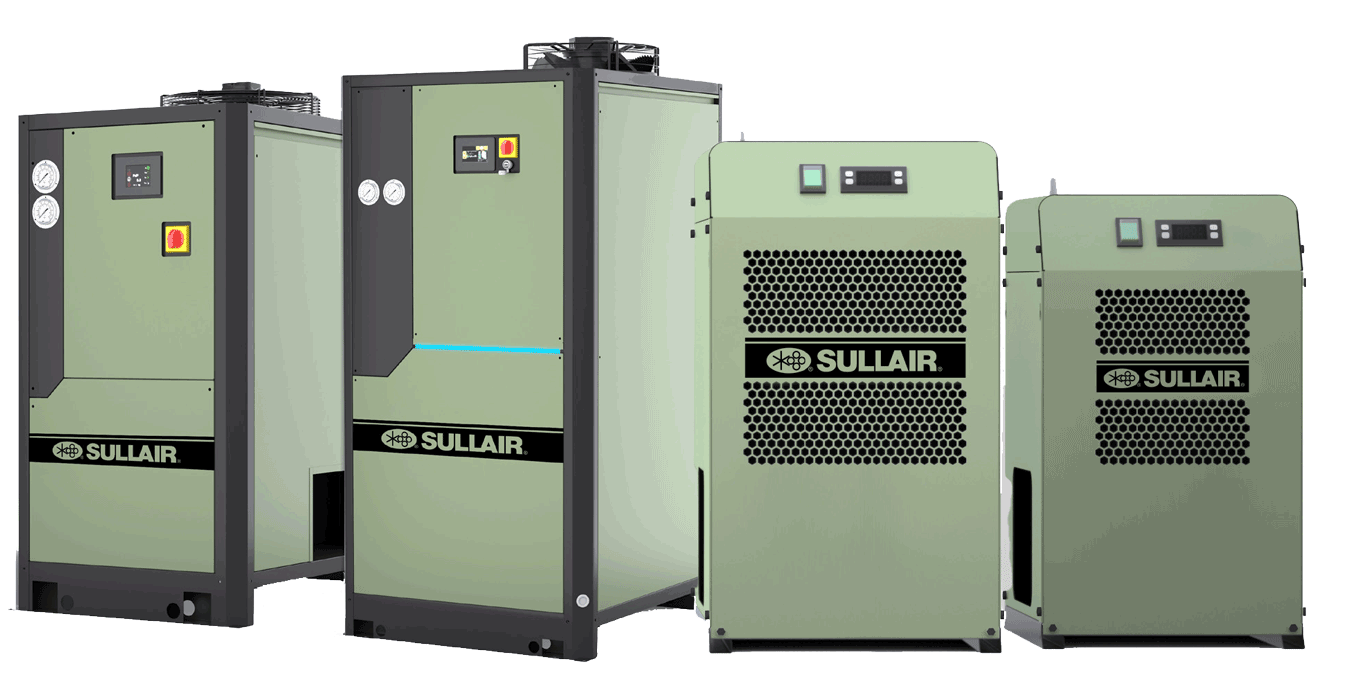

Sullair Desiccant Compressed Air Dryers are engineered for the most critical applications — providing dry compressed air where you need it most.

Compressed air contamination such as water, dust, bacteria, microorganisms and industrial acids can ruin product and foul processes. Removing these contaminants is essential to help protect your downstream equipment and reduce maintenance cost and downtime.

- Ideal for applications requiring extremely low dew point

- -40°F/-40°C (-100°F/-73°C optional)

Models vary by region. Please contact your Sullair sales representative for more details.