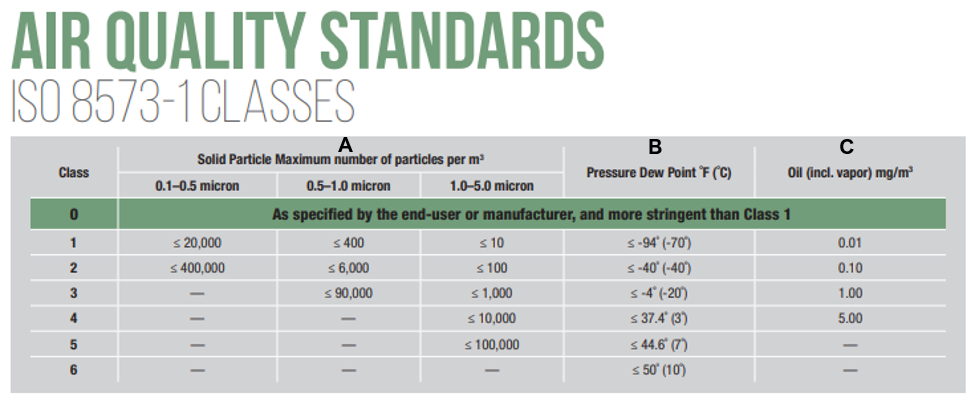

With the growing presence and demand for compressors producing Class 0 oil free air, it is easy to get confused regarding how to read, and understand, the ISO 8573-1:2010 Air Quality Classes chart. To truly understand the chart just like the alphabet we begin with our ABC’s:

Solid Particles: measures the solid particles contained in the compressed air stream. Within this column are three sub-columns indicating the quantity of allowable particles by micron size. The bigger the particle, the fewer parts per million allowed.

Pressure Dew Point: measures the maximum allowable water content in the compressed air stream.

Oil (including vapor): measures the maximum allowable oil content in the compressed air stream.

Class 0 is easy. Read horizontally. To meet the Class 0 standard, all parameters must be below the measurements listed for air quality Class 1 – solid particles; pressure dew point; and oil content. As noted, Class 0 can go a step further and specify actual parameters for these categories as required by the customer. For example, within Class 0 a user could specify counts for solid particles between 0.1 – 0.5 micron be below 10,000 per m³. The level of stringency in Class 0 is bound only by the limits of the specified ISO test for each contaminant.

Beyond Class 0, however, the air quality classes can be observed a little like a buffet where you can mix requirements between columns A, B and C. And, just like a buffet, you can skip one of the categories if that measurement is not critical to your compressed air needs.

Confused? Don’t be. It’s really as simple as 1-2-3. For this you’ll need a few pieces of information and a little bit of help from a compressed air specialist.

Identify your overall compressed air requirements. Does your operation produce food or beverages where the compressed air comes into contact with the finished goods? An oil free compressor is likely a good choice to minimize the chance of lubricant coming into contact with the product.

Identify any specific compressed air requirements within your system. For example, are there tools in your operation highly susceptible to moisture? Will the presence of excess solid particles harm your finished goods? Are there gauges and instrumentation sensitive to the presence of contaminants?

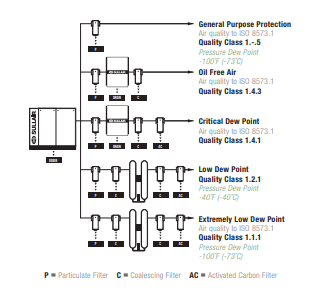

Identify the air treatment components necessary to meet your air requirements. The major categories of air treatment components include:

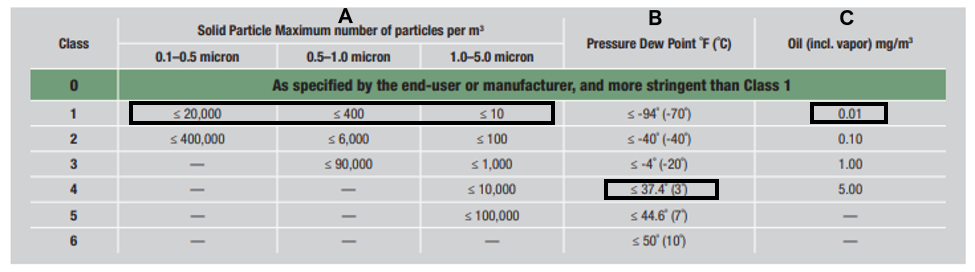

The result? With this information you can specify the compressed air requirements necessary for your operation. For example, let’s say after an analysis you determined your air class requirements are:

ISO8573-1 1.4.1

Following the chart, we would see your operation requires solid particles in row 1; Pressure Dew Point of 37.4° F or lower; and total oil including vapor of .01 mg/m³.

The following graphic shows various air quality classes and examples of the types of air treatment needed to meet the specific requirements.

Your local compressed air service partner can play a key role in helping you both understand your air quality requirements as well as the equipment and accessories needed to achieve your goals. For more information check out our previous blog on Choosing the Right Service Provider.

And when you move forward with identifying and understanding your air quality needs, just remember your ABCs and 123s!

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.