Whether we realize it or not, compressed air is used all around us in many seen and unseen applications. It is estimated that air compressors are used in 85% of manufacturing processes. Running air compressors takes energy; and energy consumption can account for up to 72% of a compressor’s lifecycle cost. It is, therefore, undeniable that compressed air is not cheap to produce and, to make matters worse, much of the energy consumed by air compressors is converted into heat. Only a small portion of energy is used for the actual process of compressing the air. Because of all this energy usage, many refer to compressed air as the fourth utility.

In this blog, we will share a few simple and quick wins to help you reduce energy and catch any air thieves in your compressed air system to maximize your air compressor’s efficiency - without the need to invest a lot of time and money.

Simple tasks such as making sure lights are turned off when vacating a room or turning off televisions and other electronic devices rather than leaving them on standby, are simple tasks we have become accustomed to doing because we have been remined of the benefits for our entire lives. The same can be said about understanding the different types of compressed air energy costs; initial investment and running costs. By educating and building awareness amongst individuals, users are armed with the tools to make potential energy saving decisions.

To find any inappropriate uses of compressed air, these are questions worth asking yourself:

An example of an inappropriate use is using compressed air for cleaning. Technicians may use compressed air for blowing and cleaning at the end of a shift. Can the air blowing be replaced by electrical blowers? It is often much cheaper to operate an air blower than to use compressed air. If the process of cleaning requires compressed air, it is worth investing in blow guns to control the flow of air used rather than using a hose with no control on the flow used.

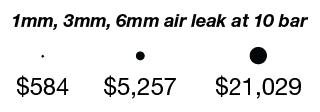

Air leaks can account for a big proportion of unplanned operational costs. An air leak from a 1 mm orifice or hole can account to 0.38 kWh assuming 20°C, 7 bar network pressure and 6.5 kW/m³/min compressor efficiency. It can add up to more than 3000 kW per year. It is vital to have regular factory walk throughs and air audits to ensure you don’t have unidentified air leaks. A small air leak can be a big thief!

Incorrect pipe sizing can be detrimental to your whole compressor system. Imagine how difficult blowing down a straw is compared to blowing down your garden hose. With the garden hose, you use less energy and effort. The wrong size piping restricts compressed air flow and pressure causing higher temperatures which all equates to increased operational costs. The installation of piping is also crucial to the overall efficiency of your system; pressure drop increases with every bend, join and coupling in your piping system. When you are pushing air through too-small pipes with many bends and couplings, you can experience a significant loss of pressure between the air compressor and the ends of the lines.[1]

Using generic air filters can not only void your warranty but can severely restrict your air compressor’s performance. Imagine your vacuum cleaner at home working at full power when the bag is full. Your vacuum cleaner will overheat and underperform and will be less efficient in picking up any dirt. Regular visual checks of air filters are key to avoiding unnecessary operational costs. Using quality parts such as Sullair high efficiency filters which have been specifically designed to work with Sullair air compressors, will provide uninterrupted, high efficiency performance in any environment. A dirty filter makes for a dirty thief!

Artificial demand is when there is excess volume of air required as a result of supplying higher pressure with no increase in productivity.[2] Here are some good questions to ask yourself:

Another point to investigate for potential energy cost savings is production pressure. Increasing the production pressure in the network by one bar will increase your energy cost by approximately 7%. There is a direct correlation between energy costs and the compression ratio of the compressor.

Reducing the overall network pressure can be a quick way to start reducing costs and reduce leakages. Using high quality in line filters can also help reduce unnecessary pressure drops that cause the air compressor to work harder. As does adhering to the recommended service schedule to keep the machinery running efficiently. Finally, using high-quality, genuine parts, filters and lubricants guarantees optimum performance, reliability and overall durability.

Take care to administer all these steps and tips and you can stop your facility’s air thief in his tracks and enjoy greater efficiency and cost savings.

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.