Our world is continuously evolving, and the overall impact of humankind is continuing to threaten life as we know it today (or perhaps even life as it previously was). To combat this, companies are finding new and innovative ways to continue going about their day-to-day business whilst considering its overall environmental impact. In this blog, we dive into the specifics around bubble curtains; understanding what they are, the applications in which they are used and most importantly the good they bring to our planet.

A bubble curtain, also often referred to as a pneumatic barrier or air curtain, has been around since the 1940’s. Whilst its use has only in recent years been truly capitalised on, Dutch engineer Johan van Veer developed the concept to reduce salt intrusion through locks given the extensive networks of canals in The Netherlands. A bubble curtain consists of a perforated pipe and a source of oil free compressed air. It is maintained on the sea or riverbed using weights attached to the tubing to anchor it to the floor.

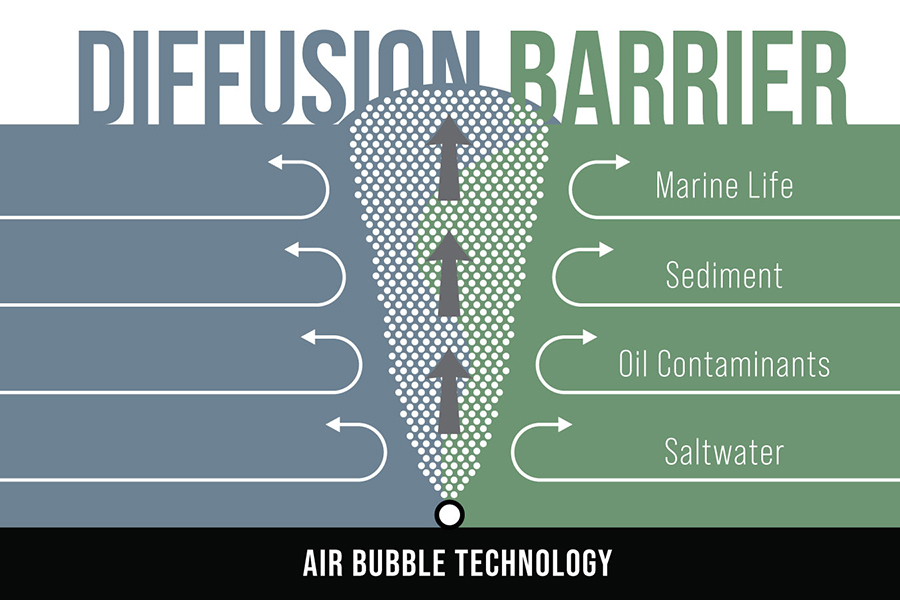

The effectiveness of bubble curtains depends mainly on the frequency of the waves, the volume of air injected, the size of the bubbles, the number of pipes used and the distance between the bubbles coming out from the diffuser pipe. The primary purpose of operating a bubble curtain is to create, more or less, a dense wall, a flexible bubble barrier, which rises continuously from the bottom of the water to the surface.

When thinking about bubble curtains, its most common applications are often linked back to the oil & gas sector. Over the last 20 years or so, large corporations have been expanding their exploration sites worldwide and in doing so have utilised the new concept of the bubble curtain. The bubble curtain has many benefits but in the case of oil & gas, its primary focus is linked to environmental protection, noise abatement and oil contamination. Bubble curtains assist in controlling oil spillages remaining effective even in treacherous weather conditions. The submersion of the curtain does not hinder oil spill recovery operations as boats and vessels can run over it. This benefit enables the recovery teams to jump straight into action with very little constraints. This new concept has enab led large corporations to become more aware of their impact on the environment whilst continuing their oil & gas exploration.

led large corporations to become more aware of their impact on the environment whilst continuing their oil & gas exploration.

When piling or drilling into the seabed, whether for new wind farm installations or bridge stanchion erections, the sound and pulses underwater is drastically amplified causing potential harm to nearby marine life. The use of a bubble curtain reduces noise emissions by up to 95% ensuring that dolphins, whales and other creatures reliant on sound wave communications are not unduly distressed. A wind farm pillar requires 4 piles, each requiring to be piled to a depth of approximately 40 metres necessitating around 3,000 blows. Without a bubble curtain in place around the piling rig during this process, the impact to the environment would be extremely detrimental. Bubble curtains also meet a need in constructional suspended sediment containment barrier applications. When working in rivers, streams or lakes, marine construction and dredging companies have started using bubble curtains retaining sediment and other suspended matter whilst continuing to allow free passage to boats and work equipment.

There are many other environmental uses for a bubble curtain which in recent years have become a very hot topic. As our world continues to suffer from human interference, we are very aware of extreme pollution in our waterways. Bubble curtains have been installed across rivers and canals assisting in directing plastic debris and pollutants to a specially designed vessel which in turn collects all the rubbish ready to be environmentally disposed of or recycled.

In addition, the formation of ice on the surface can sometimes be a hindrance, especially in those colder countries where temperatures regularly drop below freezing. A permanently installed hose system on the seabed keeps the water moving and creates an upward current. As a result, the warmer water nearer the bottom is transported to the surface and ice formation is prevented near the rising bubbles. This facility can be extremely effective in marinas, desalination plants and ports.

In recent years, the world has witnessed a rise in intense tropical storms, costing thousands of lives and devastating properties and shorelines. As human populations grow, the costs and impacts to these naturally occurring storms in the Atlantic, Pacific and Indian Oceans will continue to grow. Tropical hurricanes are generated when masses of hot and cold air collide above warm ocean water. Cooling the surface water would deprive the hurricanes of their energy source, potentially stopping them before they make landfall. Scientists have been successful in piloting a project in Norway illustrating the use of a bubble curtain across a stretch of ocean, such as a narrow straight, allowing the bubbles of compressed air to rise cold deep-sea water to the surface cooling down the warm ocean surface. By using oil free compressed air, we may be able to prevent these natural disasters from occurring and if not prevent altogether, or at least reduce the potential of them becoming stronger as they make landfall.

The use of Sullair stationary or portable oil free compressors delivers a variety of solutions for both offshore and onshore applications. The OFD1550 provides a much-needed portable solution of oil free air which can be transported around the world whilst the DSP Series provides a highly efficient electronic driven solution for those semi or permanent requirements.

From piling into the seabed, to river waste management to hurricane abatement, one thing is sure, bubble curtains have certainly proved their worth. The use of oil free compressed air is crucial in assisting and reducing our continuous impact of our ever-fragile world.

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.